The Agricultural Transformation Imperative

Modern agriculture stands at a critical juncture where technological innovation must address three simultaneous challenges: rising global food demand, environmental sustainability imperatives, and labor availability constraints. Our specialized drone manufacturing facility has responded to this complex landscape by developing custom-engineered spraying solutions that redefine precision agriculture. These aerial systems represent more than just technological advancements – they embody a fundamental shift in how we approach crop management, offering farmers unprecedented control over their input resources while enhancing operational efficiency.

Redefining Crop Protection Through Customization

Traditional spraying methodologies face growing limitations in today’s sophisticated agricultural environment:

-

Inconsistent application across variable terrain and crop canopies

-

Resource wastage from chemical drift and overlapping coverage

-

Labor-intensive operations with diminishing availability

-

Environmental impact from non-targeted chemical dispersion

Our customized spraying drones address these challenges through precision-engineered solutions that adapt to each farming operation’s unique characteristics rather than requiring farms to adapt to generic technology. This fundamental approach difference delivers superior results across multiple performance metrics.

Advanced Technical Differentiators

1. Intelligence-Driven Spraying Architecture

-

Dynamic Dispersion Control: Modular nozzle systems with micro-adjustable flow rates (0.3-18 L/min) precisely calibrated for specific crop varieties, growth stages, and chemical formulations

-

Adaptive Coverage Algorithms: Real-time adjustment of spray patterns based on environmental factors including wind velocity, humidity levels, and temperature gradients

-

Material Compatibility Matrix: Specialized tank materials and sealing systems engineered for specific chemical families (herbicides, fungicides, micronutrients) with automated purging sequences

2. Next-Generation Flight Dynamics

-

Terrain-Responsive Navigation: Multi-sensor fusion (LiDAR, stereo vision, ultrasonic) enabling 3D spatial awareness for optimal spray positioning across complex topographies

-

Micro-Climate Adaptation: Atmospheric sensors feeding data into flight control systems to automatically compensate for environmental variables affecting spray deposition

-

Obstacle Intelligence: Predictive collision avoidance using machine learning trained on agricultural obstacle patterns with multiple fail-safe protocols

3. Digital Agriculture Ecosystem Integration

-

Predictive Application Modeling: AI-driven recommendation engine analyzing historical data, soil samples, and crop conditions to optimize spraying parameters before deployment

-

Blockchain Traceability: Secure recording of all spraying activities with geo-tagged documentation for compliance, quality control, and yield analysis

-

Fleet Synchronization: Centralized management platform coordinating multiple drones for large-scale operations with load balancing and priority queuing

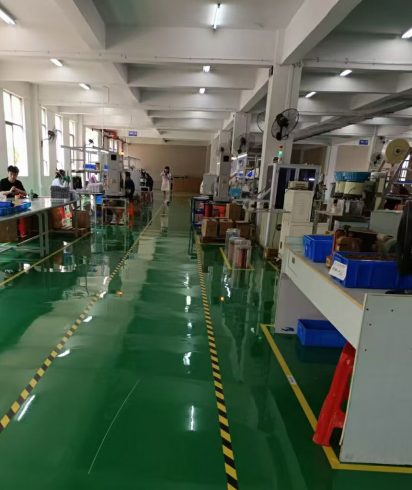

Manufacturing Excellence for Demanding Environments

Our production methodology focuses on rugged reliability and performance consistency:

-

Aerospace-Grade Materials: Carbon nanotube reinforced composites with self-healing polymer coatings for extended operational life

-

Environmental Hardening: Military-specification protection against dust, moisture, and temperature extremes (-20°C to +55°C)

-

Maintenance Innovation: Self-diagnostic systems with predictive maintenance alerts and augmented reality-assisted field service capabilities

-

Sustainable Production: Closed-loop manufacturing processes with 95% material recyclability and carbon-neutral operations

Tailored Implementation Methodology

Our client-centric approach follows a rigorous customization process:

-

Agronomic Profiling: Comprehensive analysis of farm-specific variables including soil composition, crop rotation patterns, and historical pest pressure

-

Technical Solution Design: Co-development of drone specifications with agricultural scientists and equipment engineers

-

Field Validation Protocol: Controlled environment testing followed by progressive scale-up in actual farming conditions

-

Knowledge Transfer Program: Operator certification pathway with ongoing technical support and seasonal optimization consultations

This methodology ensures our solutions deliver measurable performance improvements across diverse agricultural sectors including row crops, permanent plantings, and specialty horticulture.

Strategic Advantages for Progressive Growers

Implementing our customized spraying drones provides measurable benefits:

-

Yield Optimization: Up to 18% improvement in crop quality through precise input application

-

Economic Efficiency: 22-35% reduction in chemical costs through optimized usage

-

Environmental Stewardship: 40-60% decrease in off-target chemical deposition

-

Operational Resilience: 30-50% labor cost reduction with year-round operational capability

Schedule a technical consultation with our agricultural engineering specialists to explore how our customized solutions can address your specific farming challenges.

THE END

暂无评论内容