In an era where global food demand is rising and climate challenges intensify, modern agriculture demands innovation. Among the game-changing tools revolutionizing farms worldwide, agricultural drones—unmanned aerial vehicles (UAVs) tailored for crop management—have emerged as indispensable assets. Behind their growing adoption lies a critical enabler: specialized agricultural drone manufacturing. This article explores how dedicated factories are addressing farmers’ needs, advancing drone technology, and shaping the future of smart farming.

The Need for Purpose-Built Agricultural Drones

Traditional farming faces hurdles like labor shortages, rising input costs, and the urgency to minimize environmental impact. Generic drones, while versatile, often lack the precision, durability, and specialized features required for agricultural tasks. Farmers need tools that can:

-

Monitor crop health with multispectral or thermal imaging to detect early signs of disease, nutrient deficiency, or water stress.

-

Optimize resource use by precisely applying fertilizers, pesticides, or water—reducing waste by up to 50% compared to manual methods.

-

Operate in harsh conditions, from dusty fields to wet climates, with robust hardware and weather-resistant designs.

This is where agricultural drone manufacturers play a pivotal role. By focusing solely on farm-specific UAVs, these factories engineer solutions that go beyond “off-the-shelf” drones, delivering tools built for the unique demands of agriculture.

Key Technologies Powering Modern Agricultural Drones

Specialized drone factories invest heavily in R&D to integrate cutting-edge technology that directly benefits farmers. Here’s what sets their products apart:

1. Advanced Sensors & Imaging Systems

Drones equipped with multispectral, hyperspectral, or RGB cameras capture data invisible to the human eye. For example, near-infrared sensors identify stressed crops by measuring chlorophyll levels, enabling timely interventions. Factories collaborate with agronomists to calibrate these sensors, ensuring data accuracy for actionable insights.

2. AI-Driven Autonomy

Modern farm drones leverage artificial intelligence to automate tasks. Machine learning algorithms process real-time imagery to map field variability, plan optimal flight paths, or even detect pest outbreaks. Some factories embed edge computing capabilities, allowing drones to analyze data on-site without relying on cloud connectivity—critical for remote farms.

3. Endurance & Payload Capacity

Agricultural work often requires covering large areas. Factories design drones with high-capacity batteries or hybrid power systems (combining electric and fuel cells) to extend flight times. Additionally, modular payload systems let users swap sensors or spray nozzles, adapting the drone to tasks like planting, spraying, or yield estimation.

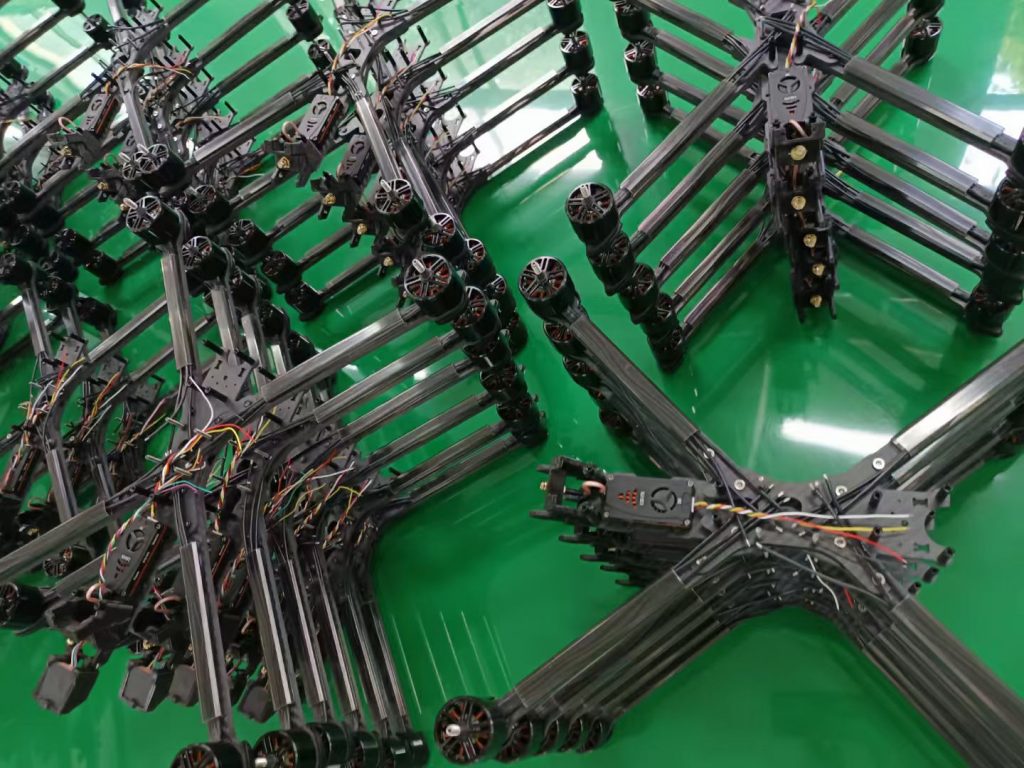

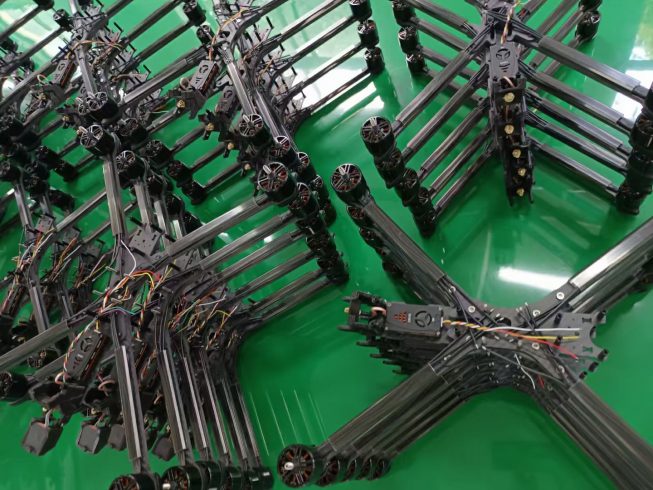

4. Durability & Ease of Maintenance

Farms are rugged environments. Leading manufacturers use corrosion-resistant materials, reinforced frames, and sealed components to withstand dust, moisture, and impacts. They also prioritize serviceability—designing drones with quick-replace parts and user-friendly maintenance protocols to minimize downtime.

Why Specialized Manufacturing Matters

Not all drone factories are created equal. Here’s why focusing on agricultural UAVs drives better outcomes:

-

Tailored Quality Control: Farms demand reliability. Specialized factories implement strict testing protocols, simulating real-world conditions (e.g., prolonged UV exposure, heavy payloads) to ensure drones perform season after season.

-

Customization Options: From adjusting spray nozzle spacing for specific crops to programming regional regulatory compliance (e.g., flight altitude limits), factories offer bespoke solutions that generic manufacturers can’t match.

-

Ecosystem Support: Beyond hardware, leading agricultural drone makers provide training programs, software integration (with farm management platforms), and responsive customer support—ensuring farmers can maximize their investment.

Impact on Sustainable Farming & Global Food Security

The rise of specialized agricultural drone manufacturing isn’t just about efficiency; it’s about sustainability. By enabling precise resource application, these drones reduce chemical runoff, lower carbon footprints (via fewer fuel-powered machines), and help smallholder farms compete with larger operations.

For instance, a 2023 study found that farms using AI-enabled agricultural drones saw a 20% increase in yield while cutting water and pesticide use by 30%. Such results are critical as the UN projects global food demand to rise by 50% by 2050.

The Future: Smarter, More Integrated Drones

As technology evolves, agricultural drone factories are pushing boundaries further. Emerging trends include:

-

Swarm Intelligence: Coordinated fleets of drones working together to cover fields faster or perform complex tasks like synchronized planting.

-

5G Connectivity: Enabling real-time data transfer to cloud-based analytics platforms, allowing farmers to make split-second decisions.

-

Sustainability Focus: Developing drones powered by renewable energy sources or biodegradable sensor components to minimize environmental impact.

Conclusion

Agricultural drone manufacturing has evolved from a niche industry to a cornerstone of modern farming. By prioritizing farm-specific needs—through advanced technology, rigorous quality control, and user-centric design—specialized factories are not just building drones; they’re building resilience into global agriculture. As these innovations continue, the sky’s the limit for how UAVs will feed a growing world, sustainably and efficiently.

For farmers and agribusinesses seeking to stay ahead, partnering with a dedicated agricultural drone manufacturer isn’t just an upgrade—it’s a step toward future-proofing their operations.

Keywords integrated: agricultural drone manufacturing, precision agriculture drones, farm drone technology, UAV for agriculture, smart farming drones, crop monitoring drones, agricultural UAV design, sustainable farming drones.

THE END

暂无评论内容